In situations elaborate fin tube layout and assembly, teaming with real experts is essential. These knowledgeable fin tube creation adepts possess a intensive perception of heat transfer principles, alloy behavior, and the cutting-edge practices for creating high-performance heat exchangers. They address everything from preliminary layout and sample production to extensive assembly and precise validation. Deciding on the right profiled tubing construction technician can significantly impact the operation and shelf life of your device.

State-of-the-art Extruded Lines

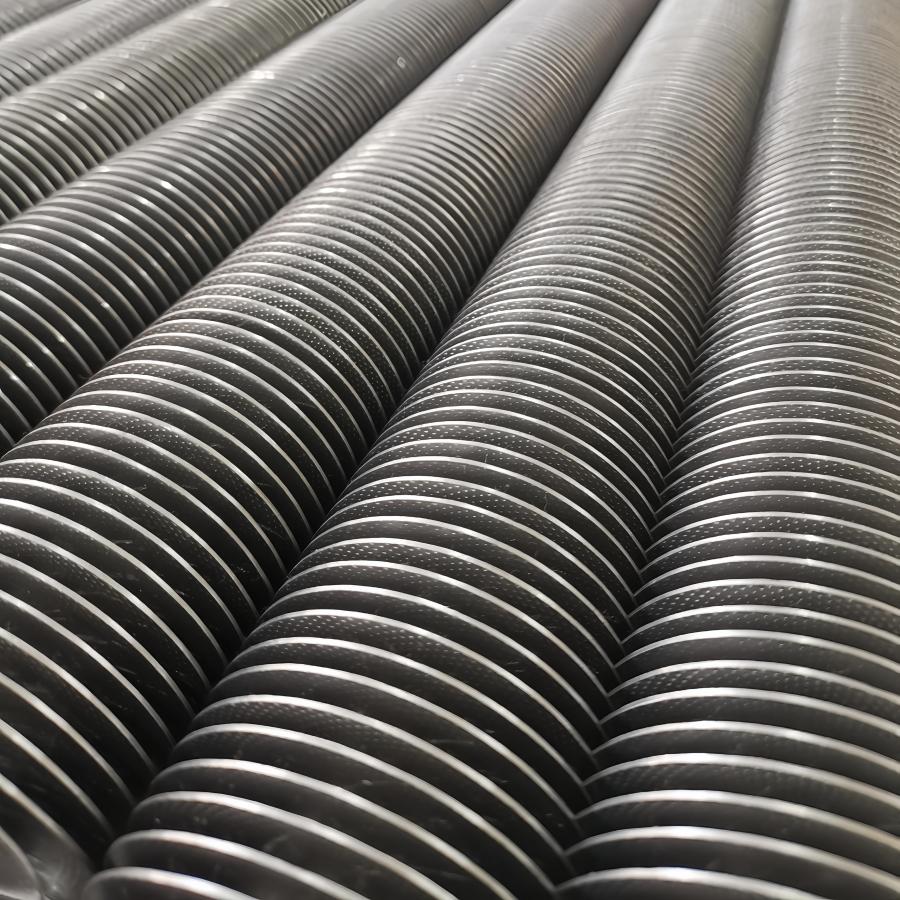

Up-to-date industrial implementations frequently demand extremely efficient energy transfer, and enhanced finned sections are necessary to achieving this. These elements contain specially designed projection geometries, regularly utilizing detailed patterns to expand the zone available for caloric exchange. Creation processes may consist of pressing, joined by meticulous fin modeling and now and then a specific surface layering to yet more improve output. Picking the compatible finned channel format is subject on the unique service situations, namely coolant properties, temperature conditions, and compression amounts.

Tailored Improved Copper Conduit Configurations

Enduring challenging thermodynamic management necessities? Our expert team engineers tailor-made copper line solutions precisely tailored to your application. We harness advanced construction techniques and specific calculations to optimize warmth movement efficiency. Whether you're in the manufacturing sector, or need high-performing cooling regarding a intricate operation, our improved copper ducts can deliver enhanced functionality. We evaluate factors such as medium flow rates, external heat environments, and shape-based constraints for produce a truly specialized and productive approach.

Consultants in Grooved Aluminum Tube Systems

For an extended period, we've been dedicated to providing unparalleled expertise in aluminum finned tube design, manufacturing, and implementation. As leading professionals, we offer a comprehensive array of services, catering to a extensive spectrum of industries, including thermal management, load supply, and reaction processing. Our unit of seasoned engineers retains a solid understanding of heat distribution principles and fabric science, ensuring that every task we undertake delivers optimal effectiveness and endurance. We believe ourselves on delivering bespoke approaches that precisely meet our clients’ unique needs. Whether you require heat dissipator repair, refurbishment, or a all-in-one system configuration, our devotion to superiority remains unwavering. Reach out us today to deliberate your precise difficulties.

Augmented Tube Engineering and Counseling Alternatives

Boosting process transfer efficiency is paramount in countless realms, and that's where specialized finned tube formation and maintenance packages truly shine. We provide comprehensive remedies encompassing everything from initial creation to full-scale integration. Our division of experienced consultants leverage advanced analysis techniques and industry best protocols to produce customized upgraded tube systems for a wide array of sensitive environments. Whether you're seeking to raise efficiency, curb power costs, or address specific functional issues, our advanced tube expertise promises peak results. We besides offer ongoing monitoring assistance to safeguard reliable effective integrity.

Cutting-Edge Precision Extended Tube Manufacturing

The prerequisites of modern heat migration systems are pushing a move towards highly focused grooved tube practices. Traditionally, ordinary fin configurations were sufficient, but now applications in cooling and industrial processing necessitate distinctly tight tolerances and detailed geometries. This involves precise manufacturing of fins directly onto the tube blank, often utilizing innovative frosty manufacturing equipment to gain the desired fin extent, clearing, and profile. Besides, the element selection plays a crucial position, with dedicated alloys frequently used to increase thermal operation while maintaining mechanical sturdiness. Criterion assessment protocols are also vital to secure stable finned tube standard.

Profiled Copper Pipe for Heat Exchangers

State-of-the-art heat distribution systems frequently utilize finned copper channel as a crucial constituent in heat exchangers. The integration of fins, frequently made from metal, significantly enhances the surface field available for heat transfer, leading to a enhanced efficient heat transfer. These grooved copper pipelines are typically found in applications ranging from industrial processes, such as refrigerating machinery, to domestic HVAC systems. The outstanding thermal heat conduction of copper, integrated with the amplified surface coverage provided by the fins, culminates in a remarkably effective method for astm b171 regulating heat. Different fin layouts, including direct and wavy, furnish varying degrees of performance upgrade depending on the certain application’s demands.

State-of-the-art heat distribution systems frequently utilize finned copper channel as a crucial constituent in heat exchangers. The integration of fins, frequently made from metal, significantly enhances the surface field available for heat transfer, leading to a enhanced efficient heat transfer. These grooved copper pipelines are typically found in applications ranging from industrial processes, such as refrigerating machinery, to domestic HVAC systems. The outstanding thermal heat conduction of copper, integrated with the amplified surface coverage provided by the fins, culminates in a remarkably effective method for astm b171 regulating heat. Different fin layouts, including direct and wavy, furnish varying degrees of performance upgrade depending on the certain application’s demands.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum profiled tubes offer a compelling combination of slim construction and remarkable effectiveness, making them ideal for a wide range of industrial heat transfer processes. Their unique formation—featuring aluminum textures attached to the tube face—significantly improves the heat exchange potential without adding substantial volume. This translates to reduced energy payments and improved overall equipment steadiness. Consequently, these tubes are frequently opted for in HVAC applications, refrigeration, and other heat movement processes where minimizing density and maximizing warmth transfer are paramount aspects.

Finned Tube Constituent Options: Red Metal & Lightweight

While considering finned tube substance, engineers frequently weigh copper and aluminum. Copper offers exceptional deterioration defense and superior thermal dispersion, making it perfect for applications where effective heat conveyance is paramount, such as in freeze systems systems. However, copper's heightened charge and potential for galvanic corrosion with other compounds can be limiting drawbacks. Conversely, aluminum provides a significantly lower valuation and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Enhancing Heat Conveyance with Finned Channels

The operation of heat appliances frequently hinges on the design and application of finned hollow bodies. These structures significantly increase the surface area available for heat flow, allowing for a much greater rejection of heat compared to simple, unfinned lines. The improvement process involves a complex interplay of factors, including fin configuration – such as fin dimension, spacing, and thickness – as well as the component of both the fins and the base lines themselves. Careful consideration of the fluid flow characteristics, whether it's air or a substance, is also paramount to ensure that the heat removal isn’t restricted by boundary layer effects or uneven dispersal of the working mass. Ultimately, a well-designed finned conduit array delivers a meaningful improvement in overall thermal output within a given space.

Hardy Finned Tube Solutions for Engineering Applications

Meeting the obligations of demanding process environments necessitates reliable heat movement systems. Our finned tube solutions are engineered for exceptional effectiveness, providing stable heat transmission in a range of applications, from chemical-processing processing to climate control. Constructed from first-rate materials and featuring advanced corrosion immunity techniques, these assemblies minimize care downtime and maximize operational effectiveness. The exclusive fin profile promotes improved heat movement, even under tough operating states.