When dealing with involved extended tube construction and manufacturing, engaging with specialized experts is vital. These capable enhanced tube making authorities possess a detailed knowledge of temperature regulation principles, fabric composition, and the cutting-edge systems for creating reliable heat exchangers. They perform everything from preliminary layout and pilot creation to bulk fabrication and detailed verification. Selecting the right profiled tubing making technician can greatly influence the operation and durability of your device.

Innovative Textured Pipes

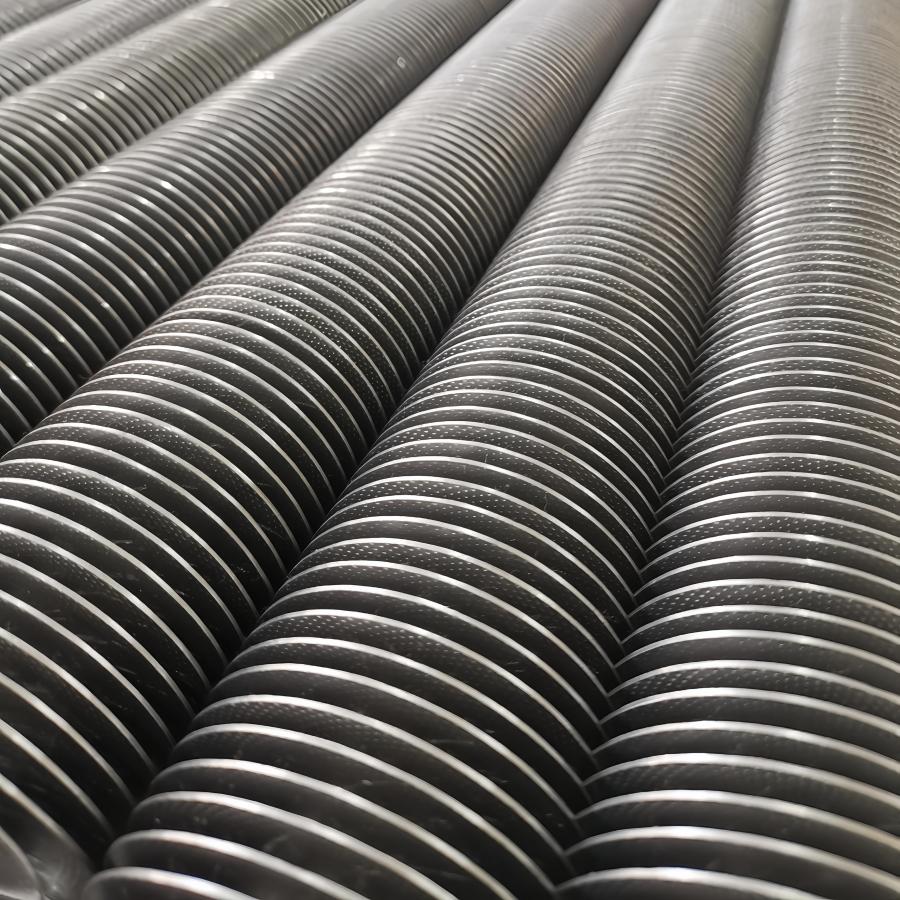

Contemporary factory facilities frequently demand remarkably efficient thermal transmission, and superior finned systems are paramount to achieving this. These components feature precisely designed ridge geometries, traditionally implementing complicated formulas to amplify the scope available for caloric communication. Building systems may entail pressing, linked by meticulous fin formation and at times a specialized surface application to extra improve operation. Picking the suitable finned line structure is dependent on the unique usage requirements, such coolant traits, warmth levels, and load levels.

Made-to-order Heat-Exchanged Metal Channel Designs

Tackling challenging warming management needs? Our professional team designs purpose-built copper line systems precisely aimed at your application. We leverage advanced building techniques and detailed calculations to raise energy spread efficiency. Whether you're in the electronics sector, or need enhanced cooling in a demanding mechanism, our augmented copper ducts can furnish increased operation. We consider factors such as gas transit rates, ambient temperature readings, and geometric constraints aimed at generate a truly singular and efficient option.

Consultants in Extruded Aluminum Tube Services

For years, we've been dedicated to providing unparalleled expertise in ribbed aluminum pipe design, construction, and integration. As leading technicians, we offer a comprehensive range of services, catering to a wide spectrum of industries, including environmental control, electrical generation, and synthetic processing. Our crew of accomplished engineers holds a profound understanding of heat transfer principles and compound science, ensuring that every task we undertake delivers optimal quality and endurance. We take pride ourselves on delivering customized plans that precisely required our clients’ unique demands. Whether you require radiator repair, restoration, or a comprehensive system plan, our commitment to outstanding caliber remains unwavering. Reach us today to consult your specialized concerns.

Expanded Tube Assembly and Assistance Packages

Refining energy transfer efficiency is paramount in countless areas, and that's where specialized enhanced tube formation and assistance offerings truly shine. We present comprehensive packages encompassing everything from initial creation to full-scale deployment. Our personnel of experienced technicians leverage advanced imitation techniques and market best protocols to develop specialized finned tube structures for a wide array of sensitive environments. Whether you're seeking to maximize capability, reduce resource costs, or fix specific engineering concerns, our extended tube expertise promises best results. We furthermore offer consistent checking assistance to secure persistent performance integrity.

State-of-the-art Precision Textured Tube Production

The demands of modern heat radiating systems are causing a development towards highly specialized radiating tube methods. Traditionally, common fin forms were allowable, but now applications in electronics and chemical processing necessitate remarkably tight tolerances and elaborate geometries. This involves exact shaping of fins directly onto the tube shell, often utilizing cutting-edge cryogenic fabrication equipment to attain the desired radiator elevation, interval, and shape. Furthermore, the constituent selection plays a decisive job, with exclusive blends frequently applied to optimize thermal performance while maintaining built robustness. Benchmark supervision systems are also essential to affirm unvarying radiating tube quality.

Augmented Copper Pipe for Heat Exchangers

State-of-the-art heat conduction systems frequently employ finned copper pipeline as a crucial ingredient in heat exchangers. The insertion of fins, frequently made from lightweight alloy, significantly expands the surface zone available for heat transfer, leading to a more efficient heat movement. These profiled copper tubes are commonly found in applications ranging from production processes, such as coolant regulation machinery, to domestic HVAC systems. The top thermal heat transmission of copper, integrated with the increased surface coverage provided by the fins, generates in fin tubes a significantly effective method for supervising heat. Different fin layouts, including even and helixed, present varying degrees of performance augmentation depending on the certain application’s standards.

State-of-the-art heat conduction systems frequently employ finned copper pipeline as a crucial ingredient in heat exchangers. The insertion of fins, frequently made from lightweight alloy, significantly expands the surface zone available for heat transfer, leading to a more efficient heat movement. These profiled copper tubes are commonly found in applications ranging from production processes, such as coolant regulation machinery, to domestic HVAC systems. The top thermal heat transmission of copper, integrated with the increased surface coverage provided by the fins, generates in fin tubes a significantly effective method for supervising heat. Different fin layouts, including even and helixed, present varying degrees of performance augmentation depending on the certain application’s standards.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum profiled tubes offer a compelling combination of streamlined construction and remarkable productivity, making them ideal for a large range of commercial heat transfer implementations. Their unique design—featuring aluminum fins attached to the tube covering—significantly amplifies the heat exchange capability without adding substantial size. This translates to lower energy spending and improved overall system trustworthiness. Consequently, these tubes are frequently selected in HVAC equipment, refrigeration, and other heat convection processes where minimizing pressure and maximizing caloric transfer are paramount concerns.

Finned Tube Constituent Options: Copper-based & Aluminium

When opting for finned tube compound, engineers frequently weigh copper and aluminum. Copper offers exceptional degradation protection and superior temperature flow, making it optimum for applications where superior heat transfer is paramount, such as in coolers systems. However, copper's greater expense and likely for galvanic corrosion with other alloys can be limiting factors. Conversely, aluminum provides a significantly lower rate and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Improving Heat Dispersion with Finned Conduits

The output of heat devices frequently hinges on the design and deployment of finned channels. These structures significantly increase the surface area available for heat dissipation, allowing for a much greater extraction of heat compared to simple, unfinned pipes. The optimization process involves a complex interplay of factors, including fin geometry – such as fin height, spacing, and thickness – as well as the constituent of both the fins and the principal tubes themselves. Careful consideration of the material flow characteristics, whether it's air or a coolant, is also paramount to ensure that the heat withdrawal isn’t restricted by boundary layer effects or uneven spread of the working substance. Ultimately, a well-designed finned pipe array delivers a important improvement in overall thermal functionality within a given space.

Resilient Finned Tube Systems for Production Applications

Conforming to the needs of demanding manufacturing environments necessitates sturdy heat distribution apparatus. Our finned tube collections are engineered for exceptional functionality, providing uniform heat conveyance in a range of applications, from fuel processing to heating control. Constructed from finest materials and featuring advanced material robustness techniques, these units minimize restoration downtime and maximize operational efficiency. The bespoke fin layout promotes greater heat transfer, even under tough operating conditions.